Good morning everyone!

Today I want to share a secret with you. That is if you are alright with that? If you are not up for a secret to be revealed, then I would tune out this morning.

The secret that I am going to share is the fact that I have worked in purchasing for a year and a half to make sure that my sales process would actually work for the sales person. I decided to take the sabbatical from sales to learn exactly what purchasing organizations are thinking when they are trying to source business. The sourcing tends to be for millions of spend annually with the organization.

I chose a well-known organization in order to learn from large scale business sourcing and what all goes into the decision. I have sat in “sourcing councils” where groups of individuals review the strategy for sourcing components and suppliers, meetings with manufacturing plants and engineering to validate suppliers, Supply Chain Industrial Certification Training, and quote comparisons. I have also been the one leading some of the projects to completion once the decision has been made on who to source business to. I have been in meetings with the buyers and the suppliers and quietly analyzed the discussions as well as picked the buyer’s brains as to how and why they make certain decisions.

I have quite a few fun stories from this time as well as what happens when the cheapest price is the sole decision for sourcing and how that decision has failed miserably…

Buyers are so busy putting out fires every day that their time is very limited. They are actually involved in a great deal of responsibilities for supply chain. They need to make sure that suppliers scorecards are accurate including, part defect rejections (PPM), incidents, financials, site evaluations, cost savings initiatives, shortages, etc. The manufacturing plants call them constantly about the supplier that are failing. Legislation changes mean that the buyers have to mitigate extra costs to the organization. Finally, they have to make sourcing decisions on new program launches. There are quite a few other responsibilities, but you should get the point that buyers are extremely busy. So, don’t waste their time!

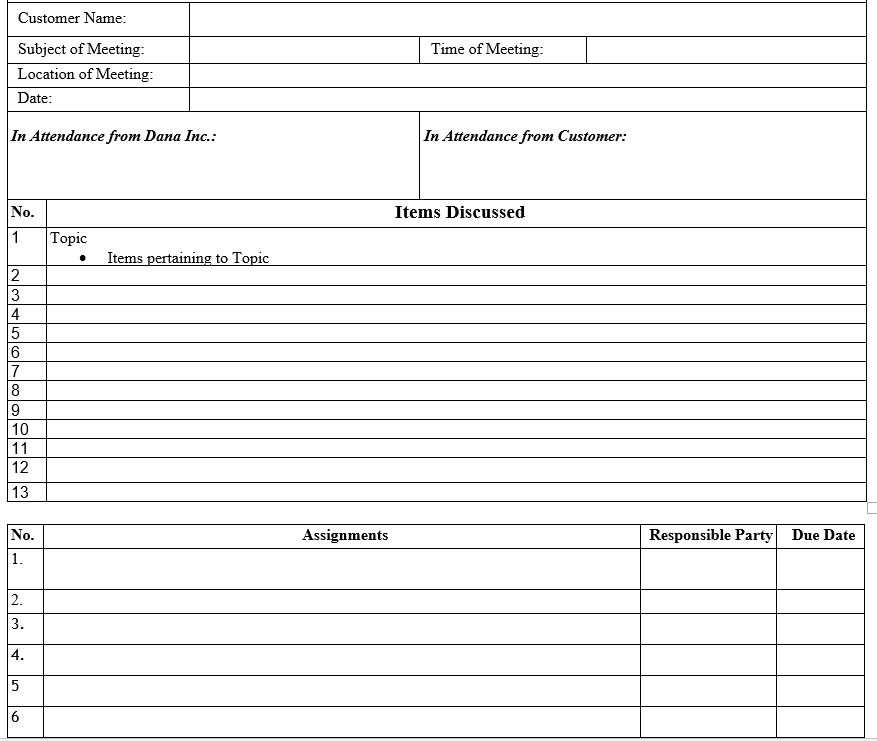

Before we get started on a few things the buyers are quietly thinking I want to highlight a couple things. First, yes they intentionally make you wait in the lobby for a few minutes and yes they intentionally have your competitor arrive for a meeting after yours to keep you off balance. Also, just because the buyer is late does not mean that you are allowed to be late to the meetings. You need to be prompt and ready to discuss whatever topic has been agreed to on the agenda. Buyers hate sales people that are unorganized, unprepared, and not on time.

So now on to three things your buyer is thinking:

1. Your Product Is A Commodity

As a sales person I know that all product offerings differ a bit, but the buyers believe that 99 percent of the products are the exact same. Have you ever wondered why the buyer has gone silent and won’t return your calls after you’ve submitted a proposal? That is because they are busy studying the cost to them with all of your incentives. What the value is to them and what your competition is offering up to them. They study a few things and compare thinking that your product that you offer is the same thing that everyone else is suppling. Now, as a sales professional we know how to differentiate our product from everyone else and using our engineering teams to assist will benefit you greatly. Make sure you know your competition’s processes and offerings better than your own so that you can position your offering that allows it to stand apart from the competition.

As a follow up make sure you are ready for the last time nibble that purchasing organizations actually have figured into their sourcing time lines. Make sure you have that extra benefit in your back pocket.

2. You Are Going to Let Them Down Like Everyone Else

Your Promises that you have provided are going to fall short which is why they lean on price as the differentiator at the beginning. Either your tooling will not be ready in time, your product will fail testing, your team will not ship on time, your low price will actually increase when you are in production, etc. It should go without saying that you need to under commit and over produce always! Make sure you are aligned with your teams when committing with your customer.

Make sure that you follow up and make sure that the products are hitting the milestones. This is where you get to babysit adults or “project manage” for your company. Nothing irritates the buyer than missing their date of a project. If you are at risk make sure you are finding alternatives to mitigate the risk for the buyer.

3. Your Company Is At Risk Of Going Out Of Business

With the competitive market and the fact that most organizations run on smaller margins these days, there is constant sensitivity that suppliers will go out of business. Buyers are subject to reprimand if their supplier suddenly sends notice that they are closing their doors. Adding fuel to the fire of scarcity with the just in time supply chains and longer payment terms elevates the risk. Make sure that you are transparent and helping them know that you are around for the long haul.

Conclusion

Buyers want to know that when they source a supplier that they are not going to regret the decision in a few months. I have had to lead projects that the decision of cheapest price has come back to haunt the team and a new decision has to be made with a secondary source. Don’t get discouraged if you don’t initially win, because most of the time the cheapest price supplier falls flat on their face and they will come calling on your trying to disguise this fact. Please do not rub it in their face. Save the victory dance until after you meet with them and you are added the extra margin into your new quote.

Serve your buyers and help them.

Sincerely,

Kevin Sidebottom

Sales and Leadership Enterprises